30 years in business.

Cooperation

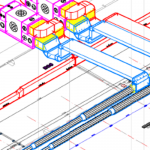

CNC Sheet Cutting Center Cutting Center

Our high-performance punching centers feature a toolbar revolver (16 + 24 Multitool), which also meets the highest technical requirements for sheet metal punching, shaping and grinding. Thanks to the press force of 230 kN, it is possible to process sheets up to a thickness of 5 mm in the form of 1200 x 2500 mm and 1565 x 3074 mm without reversing the tines.

Our high-performance punching centers feature a toolbar revolver (16 + 24 Multitool), which also meets the highest technical requirements for sheet metal punching, shaping and grinding. Thanks to the press force of 230 kN, it is possible to process sheets up to a thickness of 5 mm in the form of 1200 x 2500 mm and 1565 x 3074 mm without reversing the tines.

Sheet bending with CNC bending press

Folding and bending of different sheet metal types is custom-made according to individual customer requirements. Our machines are characterized by high constant angular accuracy achieved by CNC programming. The high precision of machines together with a wide range of available tools makes it possible to solve simple and very complicated bending shapes.

Folding and bending of different sheet metal types is custom-made according to individual customer requirements. Our machines are characterized by high constant angular accuracy achieved by CNC programming. The high precision of machines together with a wide range of available tools makes it possible to solve simple and very complicated bending shapes.

The best advantage of this technology is the high quality and accuracy of the bends.

Welding

Tungsten electrode in inert gas protection, TIG welding: electric arc welding in the protective gas is characterized by the burning of the arc between the non-smoldering electrode (using a non-electroplated net or activated tungsten) and the welded material in which the arc and the melt bath are protected by inert gas (Ar, He).

Tungsten electrode in inert gas protection, TIG welding: electric arc welding in the protective gas is characterized by the burning of the arc between the non-smoldering electrode (using a non-electroplated net or activated tungsten) and the welded material in which the arc and the melt bath are protected by inert gas (Ar, He).

Melting electrode in inert gas protection, MIG welding: Electrode melting by gas protection is provided by the inert gas of argon or helium.

Instant gas protection electrode melting, MAG welding: Electrode melting by gas protection provided by chemically active CO2 gas and mixtures thereof.

Professional sheet metal processing

Our line for professional sheet metal processing, transverse and longitudinal splitting of different types of sheet metal are transported to order, according to the individual needs of the customer. Our machines are characterized by high constant accuracy achieved by CNC programming. The very best of this technology is the very high quality.

Our line for professional sheet metal processing, transverse and longitudinal splitting of different types of sheet metal are transported to order, according to the individual needs of the customer. Our machines are characterized by high constant accuracy achieved by CNC programming. The very best of this technology is the very high quality.

Metal Finishing (powder coating plastics)

Our company has a modern painting line for surface treatment of metals by powder coatings. The sprayed material is stripped of all impurities and greases prior to the painting process itself. After application of the powder paint according to the customer’s request, it is cured in the baking furnace.

Our company has a modern painting line for surface treatment of metals by powder coatings. The sprayed material is stripped of all impurities and greases prior to the painting process itself. After application of the powder paint according to the customer’s request, it is cured in the baking furnace.

We offer comprehensive solutions

Basic informations

FIVING is a manufacturing company that since its inception in 1992 has been developing, manufacturing, assembling and servicing its own air conditioning and air conditioning equipment. The company currently employs more than 70 employees. The total flat production area occupies the area of the football stadium. FIVING puts high emphasis on the quality of its products and services, and for this reason has implemented a quality management system ISO 9001 and environmental management ISO 14001 standard.

Effective and technically advanced solutions

FIVING offers solutions in the field of air conditioning, technological cooling, heating, measurement and regulation of heating, ventilation for various types of objects in the industrial and residential spheres. We offer comprehensive and effective solutions to reduce operating costs and maximum efficiency and effectiveness of the proposed system.

Innovations

Our company realizes investment in new technologies in line with the strategic objectives of the company so as to be capable of long-term and effective to ensure the entire production process of air-conditioning equipment by own technological equipment. Our long-term goal is to be FIVING through constant innovation and improvement of quality recognized brand with first-class portfolio of products and services in the production and manufacture of air-conditioning equipment, which are the result of our own development.

News

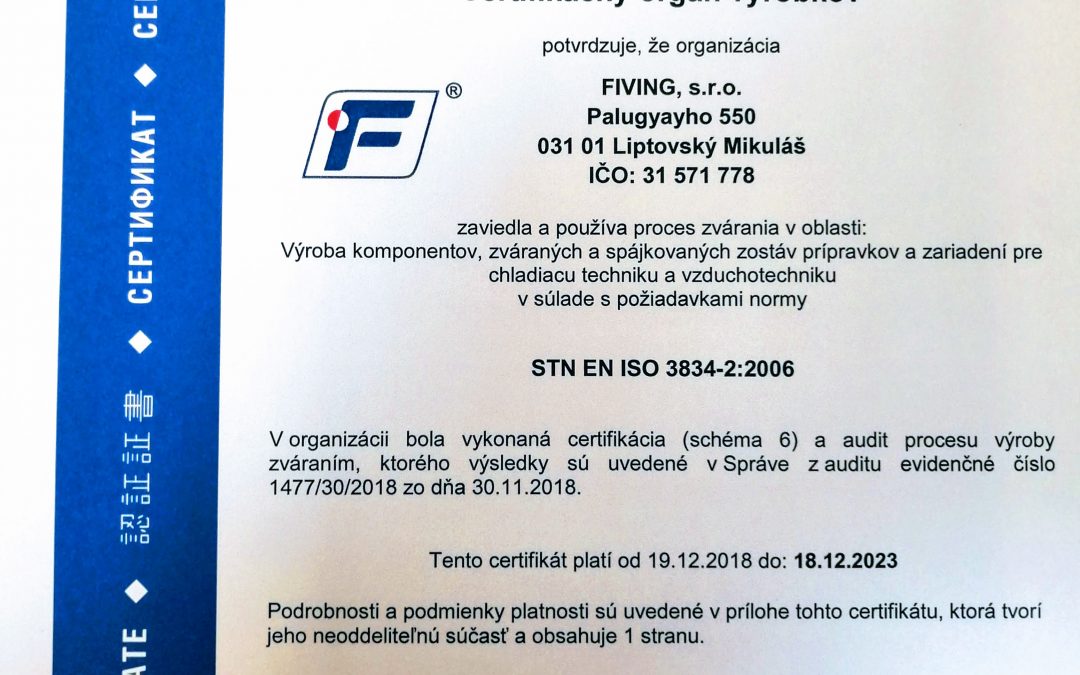

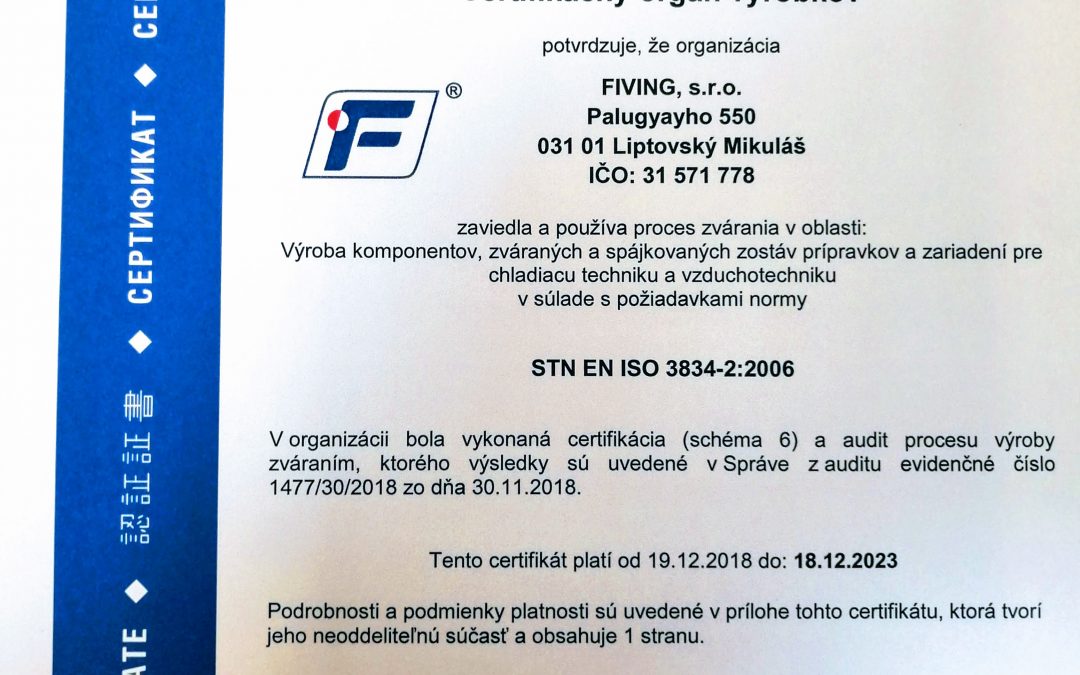

ISO 3834 certificate

We have obtained the ISO 3834 Certificate, which is a Certificate of Quality Management Systems for Welding. The ISO 3834 series of standards provides guidance on building and maintaining a functioning quality management system for melt welding of metallic materials.

We obtained certification

Fiving has acquired new certifications - ISO 9001: 2016 in the field of quality and ISO 14001: 2016 in the field of energy and the environment. The ISO 9001 standard specifies the basic requirements for a quality management system in organizations that want and need...

We offer comprehensive solutions

Basic informations

FIVING is a manufacturing company that since its inception in 1992 has been developing, manufacturing, assembling and servicing its own air conditioning and air conditioning equipment. The company currently employs more than 80 employees, service-assembling company FIVING TERM other 10. The total flat production area occupies the area of the football stadium. FIVING puts high emphasis on the quality of its products and services, and for this reason has implemented a quality management system ISO 9001 and environmental management ISO 14001 standard.

Effective and advanced technically solutions

FIVING offers solutions in the field of air conditioning, technological cooling, heating, measurement and regulation of heating, ventilation for various types of objects in the industrial and residential spheres. We offer comprehensive and effective solutions to reduce operating costs and maximum efficiency and effectiveness of the proposed system.

Innovations

Our company realizes investment in new technologies in line with the strategic objectives of the company so as to be capable of long-term and effective to ensure the entire production process of air-conditioning equipment by own technological equipment. Our long-term goal is to be FIVING through constant innovation and improvement of quality recognized brand with first-class portfolio of products and services in the production and manufacture of air-conditioning equipment, which are the result of our own development.

Cooperation

CNC Sheet Cutting Center Cutting Center

Our high-performance punching centers feature a toolbar revolver (16 + 24 Multitool), which also meets the highest technical requirements for sheet metal punching, shaping and grinding. Thanks to the press force of 230 kN, it is possible to process sheets up to a thickness of 5 mm in the form of 1200 x 2500 mm and 1565 x 3074 mm without reversing the tines.

Our high-performance punching centers feature a toolbar revolver (16 + 24 Multitool), which also meets the highest technical requirements for sheet metal punching, shaping and grinding. Thanks to the press force of 230 kN, it is possible to process sheets up to a thickness of 5 mm in the form of 1200 x 2500 mm and 1565 x 3074 mm without reversing the tines.

Sheet bending with CNC bending press

Folding and bending of different sheet metal types is custom-made according to individual customer requirements. Our machines are characterized by high constant angular accuracy achieved by CNC programming. The high precision of machines together with a wide range of available tools makes it possible to solve simple and very complicated bending shapes.

Folding and bending of different sheet metal types is custom-made according to individual customer requirements. Our machines are characterized by high constant angular accuracy achieved by CNC programming. The high precision of machines together with a wide range of available tools makes it possible to solve simple and very complicated bending shapes.

The best advantage of this technology is the high quality and accuracy of the bends.

Welding

Tungsten electrode in inert gas protection, TIG welding: electric arc welding in the protective gas is characterized by the burning of the arc between the non-smoldering electrode (using a non-electroplated net or activated tungsten) and the welded material in which the arc and the melt bath are protected by inert gas (Ar, He).

Tungsten electrode in inert gas protection, TIG welding: electric arc welding in the protective gas is characterized by the burning of the arc between the non-smoldering electrode (using a non-electroplated net or activated tungsten) and the welded material in which the arc and the melt bath are protected by inert gas (Ar, He).

Melting electrode in inert gas protection, MIG welding: Electrode melting by gas protection is provided by the inert gas of argon or helium.

Instant gas protection electrode melting, MAG welding: Electrode melting by gas protection provided by chemically active CO2 gas and mixtures thereof.

Professional sheet metal processing

Our line for professional sheet metal processing, transverse and longitudinal splitting of different types of sheet metal are transported to order, according to the individual needs of the customer. Our machines are characterized by high constant accuracy achieved by CNC programming. The very best of this technology is the very high quality.

Our line for professional sheet metal processing, transverse and longitudinal splitting of different types of sheet metal are transported to order, according to the individual needs of the customer. Our machines are characterized by high constant accuracy achieved by CNC programming. The very best of this technology is the very high quality.

Metal Finishing (powder coating plastics)

Our company has a modern painting line for surface treatment of metals by powder coatings. The sprayed material is stripped of all impurities and greases prior to the painting process itself. After application of the powder paint according to the customer’s request, it is cured in the baking furnace.

Our company has a modern painting line for surface treatment of metals by powder coatings. The sprayed material is stripped of all impurities and greases prior to the painting process itself. After application of the powder paint according to the customer’s request, it is cured in the baking furnace.

News

ISO 3834 certificate

We have obtained the ISO 3834 Certificate, which is a Certificate of Quality Management Systems for Welding. The ISO 3834 series of standards provides guidance on building and maintaining a functioning quality management system for melt welding of metallic materials.

We obtained certification

Fiving has acquired new certifications - ISO 9001: 2016 in the field of quality and ISO 14001: 2016 in the field of energy and the environment. The ISO 9001 standard specifies the basic requirements for a quality management system in organizations that want and need...

Consulting and advisory

The experience that our company has gained in 25 years of activity is the basic assumption for the complexity and professionalism of the solutions offered by us.

The experience that our company has gained in 25 years of activity is the basic assumption for the complexity and professionalism of the solutions offered by us.

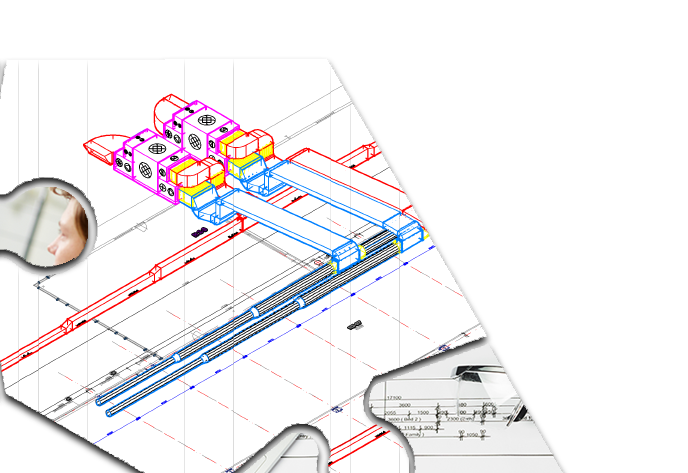

Projection and design engineering

Our designers and engineers propose to you the most appropriate technical solution that will suit your needs.

Our designers and engineers propose to you the most appropriate technical solution that will suit your needs.

Own R&D department

All products in the company portfolio are the results of constant innovation of our own R&D department.

All products in the company portfolio are the results of constant innovation of our own R&D department.

Production

FIVING company has the most advanced technology for sheet metal processing and surface treatment, which ensures high quality and flexibility in production of all our products.

FIVING company has the most advanced technology for sheet metal processing and surface treatment, which ensures high quality and flexibility in production of all our products.

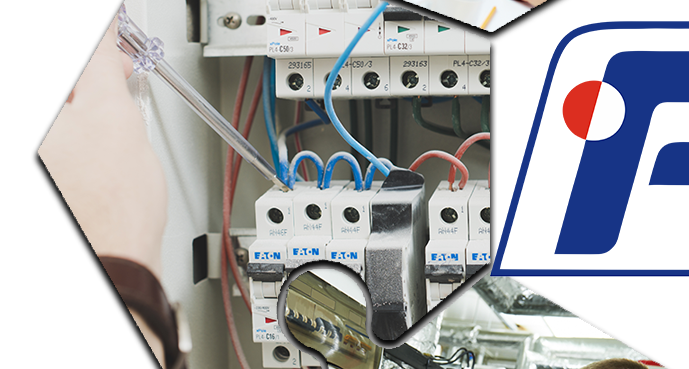

Commissioning, MaR

The right functionality and efficient regulation of the installed entire system are carried out by trained specialists with the highest qualifications and expertise.

The right functionality and efficient regulation of the installed entire system are carried out by trained specialists with the highest qualifications and expertise.

Installation and servis

Our distributors provide complete installation, assembly of ducts pipelines and warranty and post-warranty service of our devices.

Our distributors provide complete installation, assembly of ducts pipelines and warranty and post-warranty service of our devices.